Watch this IUID Compliance Demonstration

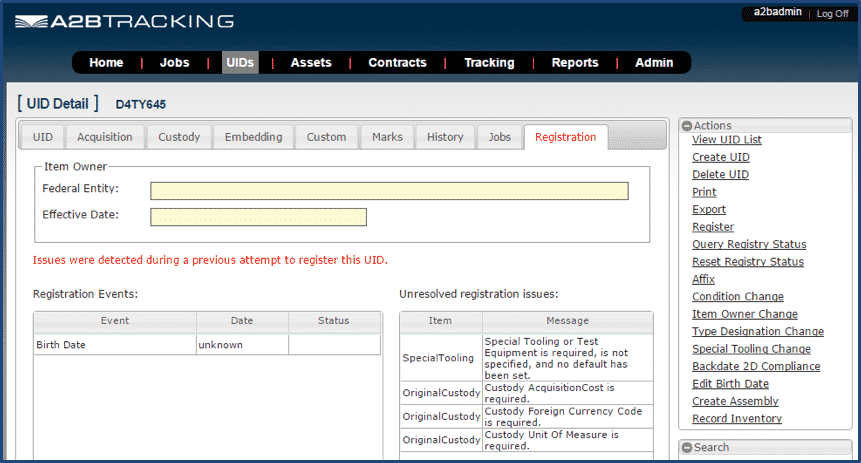

UC! Web provides a total IUID Compliance solution with easy management of asset details and IUID labels. It was designed from the ground-up to meet Military standards for asset identification (MIL-STD-130), as well as Military Shipping (MIL-STD-129) and the requirements of the IUID Policy. UC! Web’s cloud-based solution enables users to create compliant IUID labels and plates. Print, validate and verify labels for readability and accuracy, and check against assets already in the IUID Registry. The system also ensures that you have correct IUID data and provides error repair directions before mistakes are entered into the system.

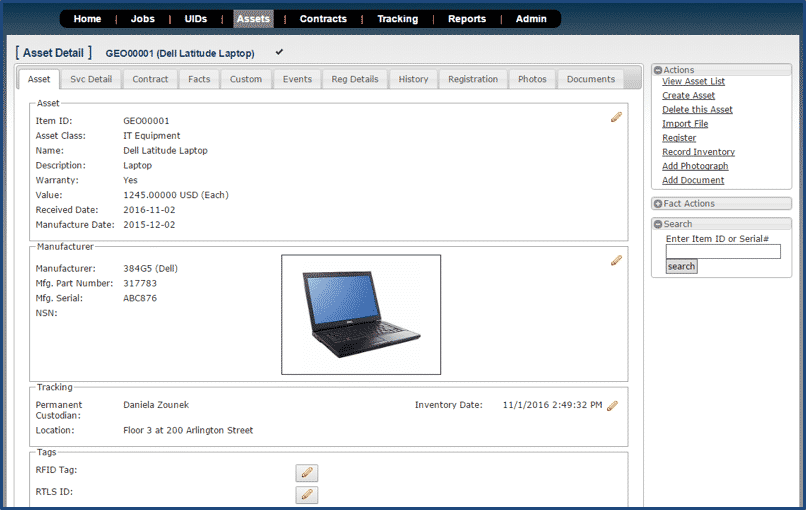

The A2B Tracking platform is a complete asset management solution that allows you to link all of the IUID data elements to your asset records for all Government deliverables, End Items and Property. Capture, manage and track items using IUID, barcodes and RFID to create a robust audit trail for all lifecycle events. UC! Web is designed to take advantage of EDI to provide a direct data exchange to the IUID Registry and WAWF. Easily submit your IUID data up to the WAWF system to fulfill your reporting obligations without ever having to enter the government portal. Saving you hundreds of hours annually from entering data into government systems.

IUID Compliance Software

UC! Web™ is specifically designed for you to comply with US military requirements and with

FAR 52.245-1 (Government Property)

DFARS 252.211-7003 (Item Identification and Valuation)

DFARS 252.245-7005 (Management and Reporting of Government Property)

It’s different from other systems because it was designed from the ground up with military standards for asset and shipment identification (MIL-STD-130, MIL-STD-129, IUID and RFID), as well as integrated reporting to WAWF and IUID Registry as core capabilities – while providing flexibility to manage all company property.

Contract Management

Manage all of your contract data, CLIN data and other line item details with seamless association to your IUID pedigree data.

UC! Web™ stores all contract details required for invoicing and shipment of new acquisitions or property contracts with receipts, shipments and inventories.

IUID Label Generation and Compliance

UC! Web™ is a military-grade cloud-based system that addresses your total IUID compliance requirements from labeling to verification to electronic reporting to WAWF and the IUID Registry.

Create linear or 2D Data Matrix barcodes and RFID labels, and register any mission critical asset or deliverable for accurate data from the very start.

Print, mark, track, ship and update the status of any asset using IUID or RFID throughout its lifecycle.

For custom IUID Labels and Plates click here

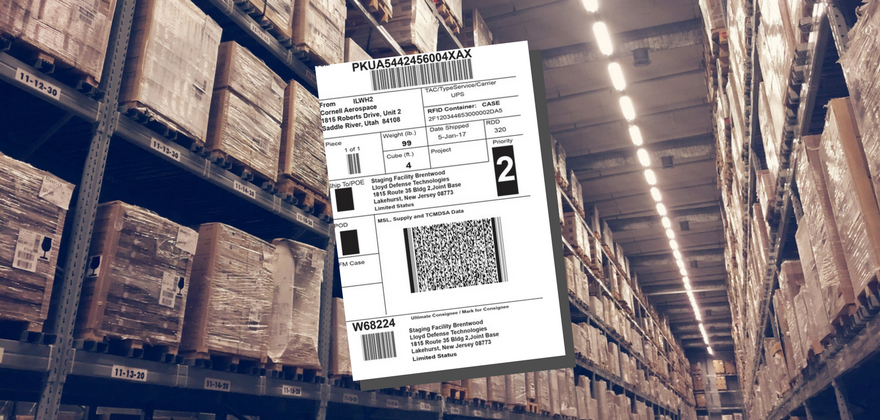

Military Shipping Label Generation and Compliance

UC! Web™ meets all of your exact specifications required for military case and pallet labels (MSLs) and MIL STD 129 compliant RFID labels.

Manage shipments and tracking with pallet, case and item level hierarchy.

UC! Web™ also automates electronic invoice submissions to WAWF. Contractors can automate Advanced Shipment Notices (ASNs) and DD250 forms.

WAWF and IUID Registry reporting

UC! Web™ is designed for your businesses or military command that needs on-time automated electronic WAWF and IUID Registry reporting without the high-cost of manual data entry.

UC! Web™ lives in the cloud, so you can manage all reportable WAWF and IUID data across multiple locations anytime, from anywhere.

Automatically receive software updates with the latest changes as government systems and policies change.

Mobility – Industrial Scanners,

Tablets or Smartphones

UC! Web™ allows computing from any device.

Scan and edit your detailed asset or shipment data and perform accurate inventories from any mobile device, tablet or smartphone with

UC! Mobile™ software.

Need more durability?

UC! Mobile™ software is pre-integrated to modern Zebra and Honeywell mobile computers for industrial environments.

Get asset visibility from remote areas and be confident you’ll always know where your assets are.

Mark, Track and Manage Assets for total IUID Compliance

UC! Web™ is your complete solution for marking, tracking and reporting assets to ensure 100% compliance to your IUID obligations.

Download this brochure to learn how UC! Web™ can support your organization.

Military Certifications

FedRAMP Certified

UC! Web™ is hosted with a FedRAMP certified cloud hosting provider that meets the US government’s standardized approach to security assessment, authorization, and monitoring for cloud-software.

ITAR

UC! Web’s cloud-based environment supports ITAR compliance for controlling unintended exports by restricting access to protected data and ensuring the physical location of that data is in the US.

Get a Personalized View

Talk to one of our IUID Compliance experts to learn more about a custom solution

for your program.

“The first major hurdle was overcome by utilizing the services of A2B Tracking. They had a great grasp of IUID requirements. The analysis phase resulted in A2B Tracking providing specific guidance regarding the actions we would need to address in order to implement a fully compliant IUID marking and registration process.”

– L3 Technologies

Selected Clients

What happens if I don’t do it?

Failed Audits

Lack of proper internal controls, self-assessments and inferior management systems can lead to failed audits, corrective actions and lost contracts.

Customer Embarrassment

Earning a military contract takes significant time and money. Failing to meet all terms of the contract erodes confidence in the eyes of your Program customers.

Risking Contracts

Non-conformance of contract requirements puts you at risk of losing your existing contract or jeopardizing your contract renewal.

What makes us better?

Complete

Asset Management

UC! Web™ manages corporate property, all military assets and shipments, property transfers and asset lifecycle events with direct reporting to government systems.

Automation to WAWF

and IUID Registry

UC! Web™ was designed from the ground up with military standards for asset and shipment identification (IUID and RFID) as well as integrated WAWF and IUID Registry reporting as core capabilities yet flexible enough to handle all company property.

Fast to Deploy

and Integrate

UC! Web™ is a single cloud-based system, fully integrated. No confusing modules or costly separate purchases which makes the entire system deployment fast and simple.