The branches of the US Military and contractors that support them have all made significant strides towards the FIAR initiative and becoming “Audit Ready”. But there is still a long way to go! The process of capturing and reporting all assets to the IUID Registry whether they are legacy items, Government Furnished Property or newly acquired assets, is a daunting task.

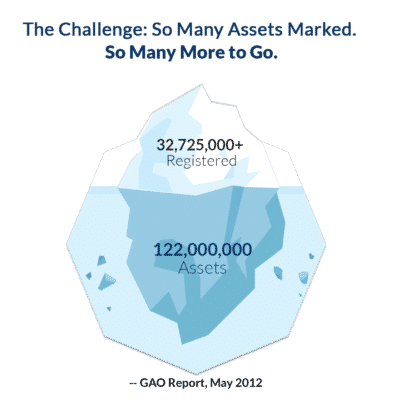

According to a May 2012 GAO Report there are approximately 122 million total legacy items that qualify for reporting to the IUID Registry. (GAO report: http://www.gao.gov/products/GAO-12-482)

Assets registered in the IUID Registry

In early 2017, the IUID Registry reported there’s an excess of 32,705,000 assets that are registered, which is still only a fraction of the total estimated number of assets in the DoD.

According to the GAO May 2012 assessment, there are an estimated 122 million assets that need to be accounted for using the correct approach or methodologies.

Fortunately, the DoD has embraced the Asset Tracking Industry best practices for quickly and cost-effectively identifying, marking, and tracking critical assets. The DoD refers to this practice as the Item Unique Identification (or IUID). They have adopted a number of policies to streamline and simplify this process, most notably the IUID Policy.

The DoD has also put into place the WAWF e-commerce suite which includes iRAPT and the IUID Registry. This is a gateway to reporting all military assets and shipments.

Auto-ID Technology

It’s important to reflect on the benefits of Auto‑ID technology because it’s a best practice for identifying the assets and the uniqueness of those assets from cradle to grave. From the moment the assets are in design, the performance, location, and readiness of those assets are crucial to the best practices of asset management throughout its lifecycle.

Keep in mind: total asset visibility is the goal. Accurate information on the location of items, quantity, condition, and the status is critical. If you have the appropriate information to buy only what you need, you can reduce the cost of buying spares.

Auto‑ID technology eliminates the slow, error‑prone manual process of attempting to track assets by spreadsheets. The manual process can be fraught with error and loaded with the time‑consuming efforts of combing through records and physical inventories.

The manual process is often a root cause for the inability to perform cycle counts and other inventory maintenance procedures. In many organizations, cycle counts never get done to the full extent because there’s not enough time to achieve that level of inventory accuracy.

Auto ID technology and IUID is data accuracy from the start. For contractors, data accuracy translates to saving time and then getting paid faster. It also means effectively utilizing resources. Commercial organizations outside the military have been proving this for the past 50 years. If you are tracking and identifying items in a warehouse, there are people that say, “If it doesn’t have a barcode associated with it, it doesn’t exist.” This is because the information systems improves your ability to know what’s in the warehouse with just a keyboard.

To learn more about the assets registered in the IUID Registry and how the DoD has embraced Auto ID technology as a system to address this problem, watch this video segment from our recent FIAR webinar.